Qingdao JCWY Environmental Protection Technology Co., Ltd.

Qingdao JCWY Environmental Protection Technology Co., Ltd.

Qingdao JCWY Environmental Protection Technology Co., Ltd.

Qingdao JCWY Environmental Protection Technology Co., Ltd.

Poultry house anaerobic reactor assembly tank double film biogas holder integrated anaerobic equipment biogas generator purification environment equipment

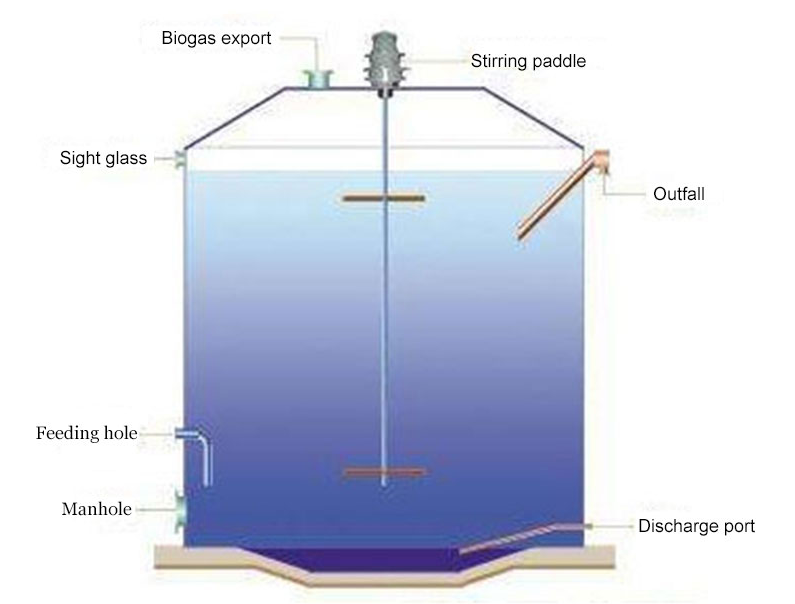

CSTR reactor refers to a tank reactor with a stirring paddle, also known as a continuous stirred tank reactor, referred to as CSTR. It is an anaerobic treatment technology that allows the fermentation raw materials and micro-organisms to be completely mixed.

1. The reactor is capable of processing raw materials having a high suspended matter content;

2. The temperature inside of the fermenter is evenly distributed;

3. The material in the anaerobic fermentation tank is evenly distributed;

4. The anaerobic fermenter has high impact load resistance;

5. Anaerobic fermenters avoid scum, crusts, blockages, poor gas escape and short-flow phenomena;

6. Combined with flexible airbags, it is an integrated device, saving investment and land occupation. It is one of the most advanced anaerobic reactors in the world.

It is applied to slaughter wastewater, livestock and poultry manure treatment in cattle, pigs, chickens and other farms, biogas production and power generation projects; kitchen waste treatment, straw biogas production, biogas production, high suspended solids alcohol wastewater, municipal sewage sludge High-concentration organic wastewater treatment project with more SS.

1.Easy to install and easy to use.

2. During the work process, no personnel are required to be on duty, and the materials are renewed regularly.

3. The desulfurization efficiency is high, and the effect of recycling can be achieved by oxidation reduction in the later stage.

4. Fine desulfurization, high precision of desulfurization.

5. Initially low investment and medium operating costs.

It is mainly used for the removal of corrosive hydrogen sulfide (H2S) gas in biogas, and can also be used for other purification of hydrogen sulfide gas, so that the treated gas provides safety for the normal use and service life of the required equipment.

First step: Fe2O3 · H2O + 3 H2S = Fe2S3 + 4 H2O (desulfuration)

Second step: Fe2S3 + 3/2 O2 + 3 H2O = Fe2O3 · H2O + 2 H2O + 3 S (regeneration)

The service life span | Above 30 years |

The thickness of the coating | 0.28~0.40mm |

Resistance to acid and alkali performance | The special coating to adapt to the range of pH:1~14 Standard coating to adapt to the range of pH:3~11 |

Porcelain enamel Coating Adhesion | 3450 N/cm |

Steel Plate Elastic | The same with steel plate, about 500 kN/mm |

Coating Hardness | 6.0~7.0/Mohs hardness |

Spark test | >1500V |

Permeability | Gas and liquid can not penetrate |

Resistance to corrosion | Very good, suitable for waste water and strong brine, sea water, high sulfur crude oil, salt fog, organic and inorganic compounds |

Easy to clean | Smooth, inert, luster, adhesion resistance |

A. We have ourown technical teams, so we candesign, fabricate and installthis steel structure workshop according to customers requirement. |

B. It's very easy to install the steel structure workshop in your there according to our installation drawings. Also, we will supply alltechnical supportduring installation and after-sale service. |

C.One stop shoping---we offer not only steel structure but alsosandwich panelsandall the accessories. It will ensure the perfect integration between each part. |

D. Fast construction, easy installation, stable structure, earthquake proofing, energy conserving and environment protection. |

E.We have prettygood preservative treatmenton this steel frame as follows, a. Clean the steel( reach to Sa2.5 Grade, China Code), then we will spray paint: 2 layer epoxy zinc rich primer and 2layer antirust paint( total thickness: 100-120um); Warranty period: 18-20 years under normal conditions. b. Hot-dipped galvanized, when the thickness of parts is less than5mm, thickness of hot-dipped gal is more than65um; when equal to or more than 5mm, that is more than 86um. Warranty period: 45-50 years under normalconditions. |

Type | Construction building |

Wide span | Single span or multiple spans, the max span clear distance is 36m, without middle column |

Roof and Wall | Option: Steel sheet,EPS, fiber glass, rock wool or PU sandwich panel |

Door and Window | PVC or Aluminum alloy; sliding door or rolled door |

Column and Beam | Option: hot rolled or welded H section, I section; painting or galvanized |

Purlin | Option: C-section or Z-section |

Local Climate | 1. Wind speed2. Snow load3. Rain quantity4. Earthquake grade if have more details is preferred. |

Usage | For the Broiler |

Drawing | 1. According to clients' drawing |

2. Design as per clients' dimension and requests | |

Package | Naked loaded in shipping container or as per requests. |

Equipment | According to the requirements of the customers |