Qingdao JCWY Environmental Protection Technology Co., Ltd.

Qingdao JCWY Environmental Protection Technology Co., Ltd.

Qingdao JCWY Environmental Protection Technology Co., Ltd.

Qingdao JCWY Environmental Protection Technology Co., Ltd.

Biogas digester liquid mixing tank anaerobic tank on sale

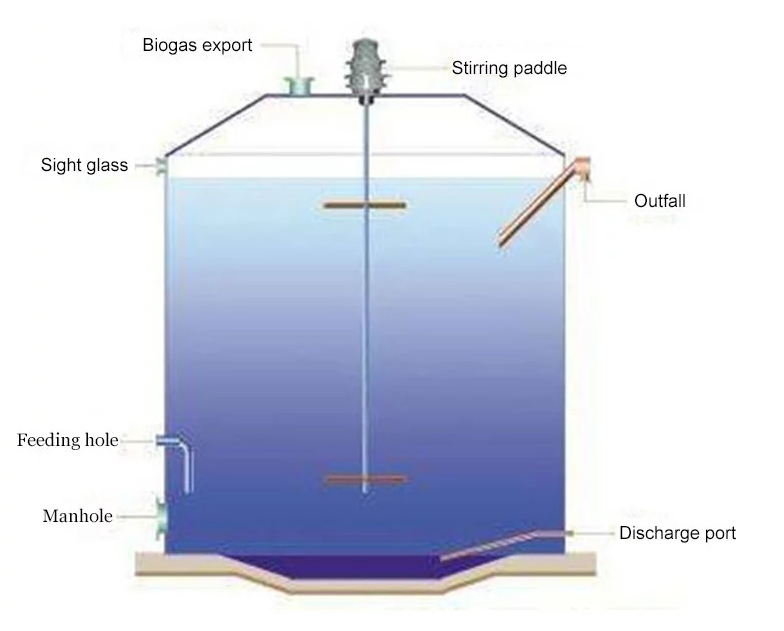

CSTR reactor refers to a tank reactor with a stirring paddle, also known as a continuous stirred tank reactor, referred to as CSTR. It is an anaerobic treatment technology that allows the fermentation raw materials and micro-organisms to be completely mixed.

1. The reactor is capable of processing raw materials having a high suspended matter content;

2. The temperature inside of the fermenter is evenly distributed;

3. The material in the anaerobic fermentation tank is evenly distributed;

4. The anaerobic fermenter has high impact load resistance;

5. Anaerobic fermenters avoid scum, crusts, blockages, poor gas escape and short-flow phenomena;

6. Combined with flexible airbags, it is an integrated device, saving investment and land occupation. It is one of the most advanced anaerobic reactors in the world.

It is applied to slaughter wastewater, livestock and poultry manure treatment in cattle, pigs, chickens and other farms, biogas production and power generation projects; kitchen waste treatment, straw biogas production, biogas production, high suspended solids alcohol wastewater, municipal sewage sludge High-concentration organic wastewater treatment project with more SS.

The service life span | Above 30 years |

The thickness of the coating | 0.28~0.40mm |

Resistance to acid and alkali performance | The special coating to adapt to the range of pH:1~14 Standard coating to adapt to the range of pH:3~11 |

Porcelain enamel Coating Adhesion | 3450 N/cm |

Steel Plate Elastic | The same with steel plate, about 500 kN/mm |

Coating Hardness | 6.0~7.0/Mohs hardness |

Spark test | >1500V |

Permeability | Gas and liquid can not penetrate |

Resistance to corrosion | Very good, suitable for wastewater and strong brine, sea water, high sulfur crude oil, salt fog, organic and inorganic compounds |

Easy to clean | Smooth, inert, luster, adhesion resistance |